Easy accessibility. Completely removable walls for easy and total access to the internal components.

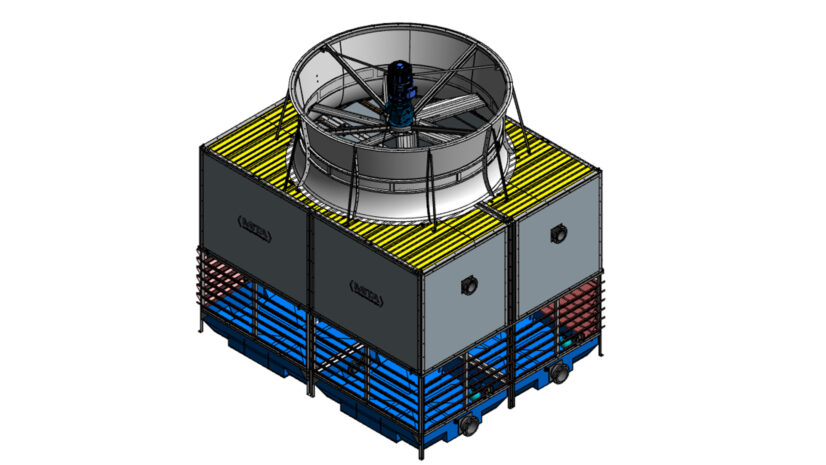

PME-E Open-Circuit Evaporative Cooling Tower

for medium to large systemsA light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

High efficiency. Provided by evaporative technology.

Limited noise levels. Sound reducing solutions on customer request.

Efficiency and optimal resourse use. MITA solutions are selected through advanced software in order to fit the plant characteristics.

Quick pay-back. Pre-selection performed together with the client, based on their project requirement.

Industry 4.0. Possibility of control, monitoring and data collection on company management system.

How it Works

The PME-E open evaporative tower uses the efficient principle of evaporative cooling: the forced evaporation of a small quantity of water causes a drop in the temperature of the main water mass. The corrosion-proof fibreglass sandwich panelling ensures that the equipment is lightweight.

All models are fully pre-assembled in our factory.

PME-XL is an extension of the PME-E range: a single PME-XL cell can dispose of up to about 5 MW, with important results in terms of installed power and noise. This solution is particularly suitable for projects where multiples of PME-E were previously offered.

BIM File

Download PME-E on SkeinforceTechnical Features

- Axial motor-fan with direct coupling, low installed power, low noise levels.

- Support structure in hot dip galvanized steel after fabrication.

- Distribution system in PVC or PP equipped with wide non-clogging PP spray nozzles.

- Fill pack with different kinds of air/water channels, suitable for the use with different water types.

- Certified PP drift eliminators (entrainment 0.01%).

- Tank with sloping base entirely made of fibreglass.

- Capacity: from 860 kW to 5 MW (indicative capacity referring to a machine, thermal gradient 5°C).

Environmental and economic sustainability of PME-E open cooling tower

- Use of water for efficient heat transfer (i.e., cooling of the process fluid).

- Low and further optimizable energy use.

- Extremely small installation spaces.

- Falls within the product categories that MITA is able to regenerate.

- Indication of “carbon footprint” from the MITA team.

Some MITA projects

Industrial Cooling Towers for a Steel Processing Plant in Sweden

MITA Cooling Technologies supplied two PMM open-loop towers for the Swedish multinational steel processing company SSAB: a few years later, we are receiving very positive feed-back regarding the technical solution and performance.

Learn MoreIndustrial Cooling Tower for Coca Cola in Kiev

A MITA cooling system serving one of the world's most celebrated multinational food & beverage companies: the Kiev-based Coca-Cola now uses a PME-E evaporative tower for its production facilities.

Learn MorePME-E Cooling Towers for RAI in Rome

MITA cooling systems also serve the air conditioning system of the historic Italian Radio Television center at 66 Via Teulada, Rome: they are the PME-E open-circuit cooling towers.

Learn MoreDownloads

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Your Plant Needs

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.